Efficiency, speed, and quality are critical in today’s increasingly competitive global market. That’s why more companies are turning to an end-to-end manufacturing partner to streamline production, reduce costs, and improve product quality. Whether you’re a startup scaling up or a global enterprise optimizing supply chains, working with a full-service partner like Panasia Solutions delivers measurable advantages across the board.

Here are some of the key benefits of choosing an end-to-end manufacturing partner, with industry insights and real-world examples to help you make informed decisions for your business.

What Is an End-to-End Manufacturing Partner?

An end-to-end manufacturing partner handles the entire product lifecycle – from design and prototyping to manufacturing, assembly, quality control, packaging, and even logistics. Unlike traditional manufacturers that only handle part of the process, end-to-end partners provide a seamless, integrated production solution.

This approach significantly reduces the complexity, cost, and risk involved in working with multiple vendors. According to a 2024 report by Deloitte on digital manufacturing, companies that leverage integrated manufacturing partnerships experience a 30% faster time-to-market and up to 25% cost savings on average.

Why Choose an End-to-End Manufacturing Partner?

Partnering with a company like Panasia Solutions, which offers complete manufacturing services, brings several key advantages:

1. Streamlined Communication

Managing multiple suppliers can create communication gaps that lead to delays and quality issues. With an end-to-end partner:

- All teams work under one roof or are centrally coordinated.

- There’s a single point of contact for project oversight.

- Miscommunication is minimized, improving efficiency.

2. Faster Time-to-Market

Every stage of the production cycle is coordinated for speed and precision. This is especially valuable in sectors like consumer electronics and automotive, where time-to-market can determine profitability.

3. Greater Cost Efficiency

By consolidating services:

- Overhead costs are reduced.

- Procurement is streamlined.

- Waste is minimized thanks to real-time feedback across the production chain.

According to McKinsey & Company, integrated supply chains can reduce production lead times by 15-20%.

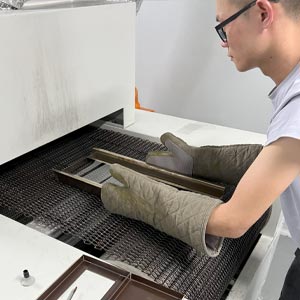

4. Improved Product Quality

Panasia Solutions applies consistent quality control measures from start to finish, ensuring:

- Less rework.

- Higher customer satisfaction.

- Compliance with industry standards and certifications.

5. Scalability and Flexibility

Whether you’re scaling production up or down, an end-to-end partner like Panasia can adjust quickly without the need to re-contract multiple vendors.

Panasia Solutions: Your Trusted End-to-End Manufacturing Partner

Panasia Solutions is a market leader in end-to-end manufacturing with a strong track record across industries such as electronics, lighting, telecom, and consumer products. What sets Panasia apart?

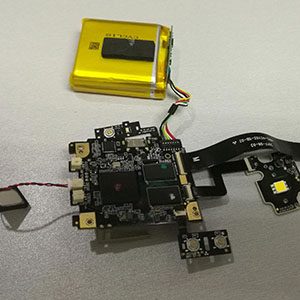

- In-house capabilities: From PCB design and injection moulding to final assembly.

- Global sourcing network: Ensuring component availability and competitive pricing.

- Agile production systems: Adapting to client needs with speed and precision.

- Sustainability commitment: Integrating eco-conscious practices throughout the process.

Whether you’re launching a new product or optimizing an existing one, Panasia’s comprehensive services offer unmatched value, innovation, and reliability.

When Is the Right Time to Partner with an End-to-End Manufacturer?

Consider working with an end-to-end manufacturing partner when:

- You’re entering a new market and need rapid production scalability.

- You’ve experienced delays or cost overruns with fragmented supply chains.

- Your product requires multi-disciplinary expertise, such as combining electronics with mechanical parts.

- You want to focus on innovation and sales, while your manufacturing partner handles production.

Key Takeaways

Working with an end-to-end manufacturing partner helps businesses:

- Reduce costs and lead times.

- Improve product consistency.

- Simplify supplier management.

- Increase speed-to-market.

- Scale efficiently.

Ready to Take Your Manufacturing to the Next Level?

If you’re looking for a reliable, innovative end-to-end manufacturing partner, look no further than Panasia Solutions. With decades of experience, cutting-edge facilities, and a client-first mindset, Panasia delivers results that help your business thrive.